quiet revolution

qr5 vertical axis wind turbine

Prior to University, I obtained a paid year-long internship as part of the Mechanical Engineering team of quietrevolution, a ‘small-wind’ turbine manufacturer. I also sometimes contributed to the Commercial team as customer service and sales assistant at fairs.

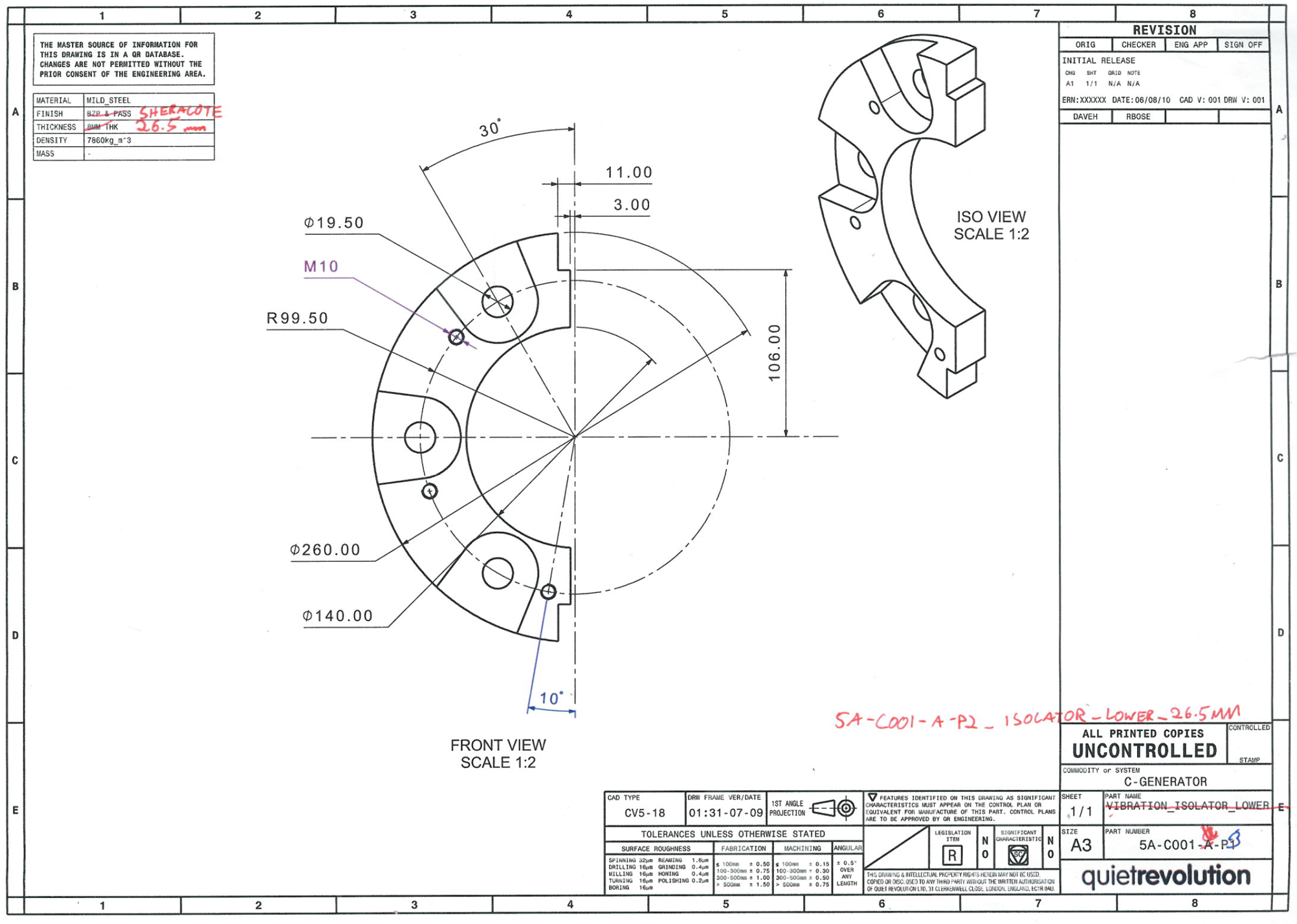

Worked on various projects throughout the year, such as designing a frame to use hydraulic rams to join mast sections together, and the redesign of the vibration and electrical isolator.

Symmetrical isolator plate design

The original vibrational and electrical isolators used in the turbines were two mild steel discs joined together by a middle layer of rubber. I saw that the rubber was often heavily damaged after prolonged use. In addition, these discs were very hard to remove as they required the removal of the wind turbine rotor above, and were also bespoke parts, adding unnecessary costs. I sent a product specification to firms to try and obtain off-the-shelf components and finalised a design after meetings with numerous suppliers.

The new design used several small, easily replaceable isolators mounted on a disc. However, a normal disc would still require the removal of the rotor when replacing/retro-fitting; I thus designed a custom disc to split into two symmetrical parts, easing inspection and maintenance. The target cost was to be