3d printed pressure sensors

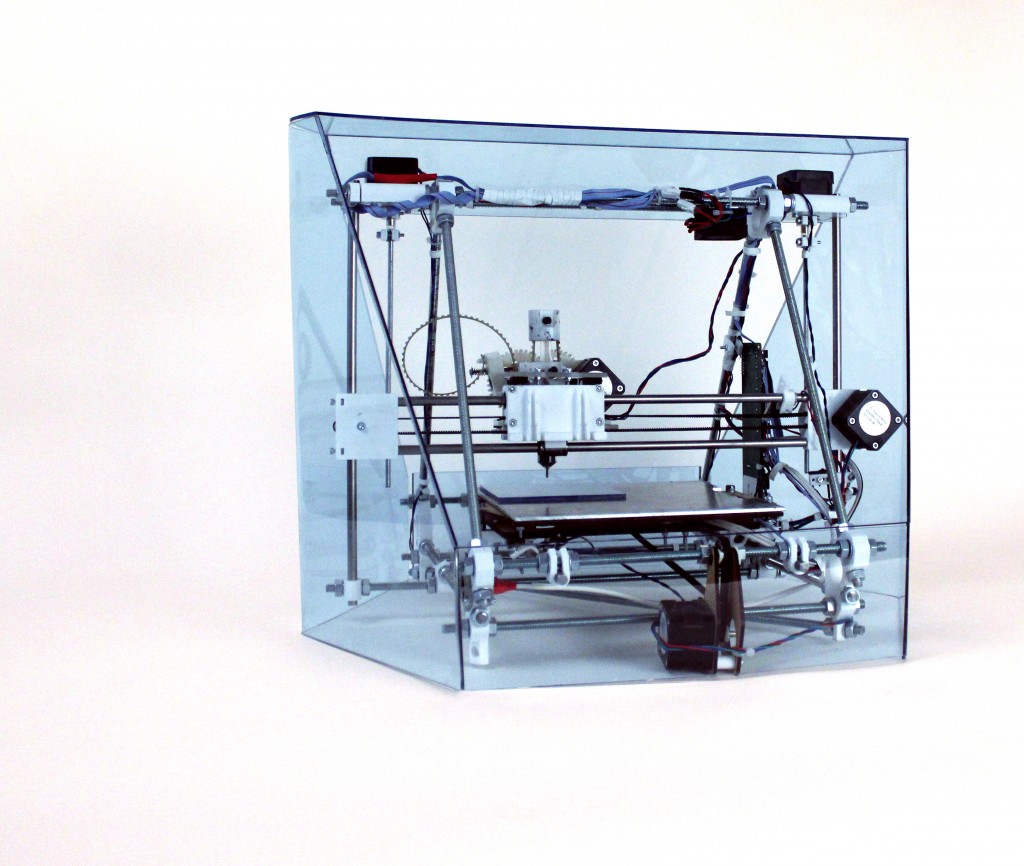

Final prototype of pressure sensor manufacturing Reprap.

The aim of this project is to develop novel pressure sensors for use in racing wheelchairs in order to reduce users' pressure-ulcers. The concept that was developed is to use a commercially-available Reprap 3D printer to print sensors onto a mat with conductive paint, using a modified paste extruder. An Arduino script was written to measure the imposed pressure on each sensor, by measuring the capacitance between the printed sensors and the human body. These values are then displayed on a grid on the computer via a Processing script. The codes written for the prototype can be easily expanded for as many sensors as is required.

The printer is now currently being developed and expanded for use with various biomaterials.

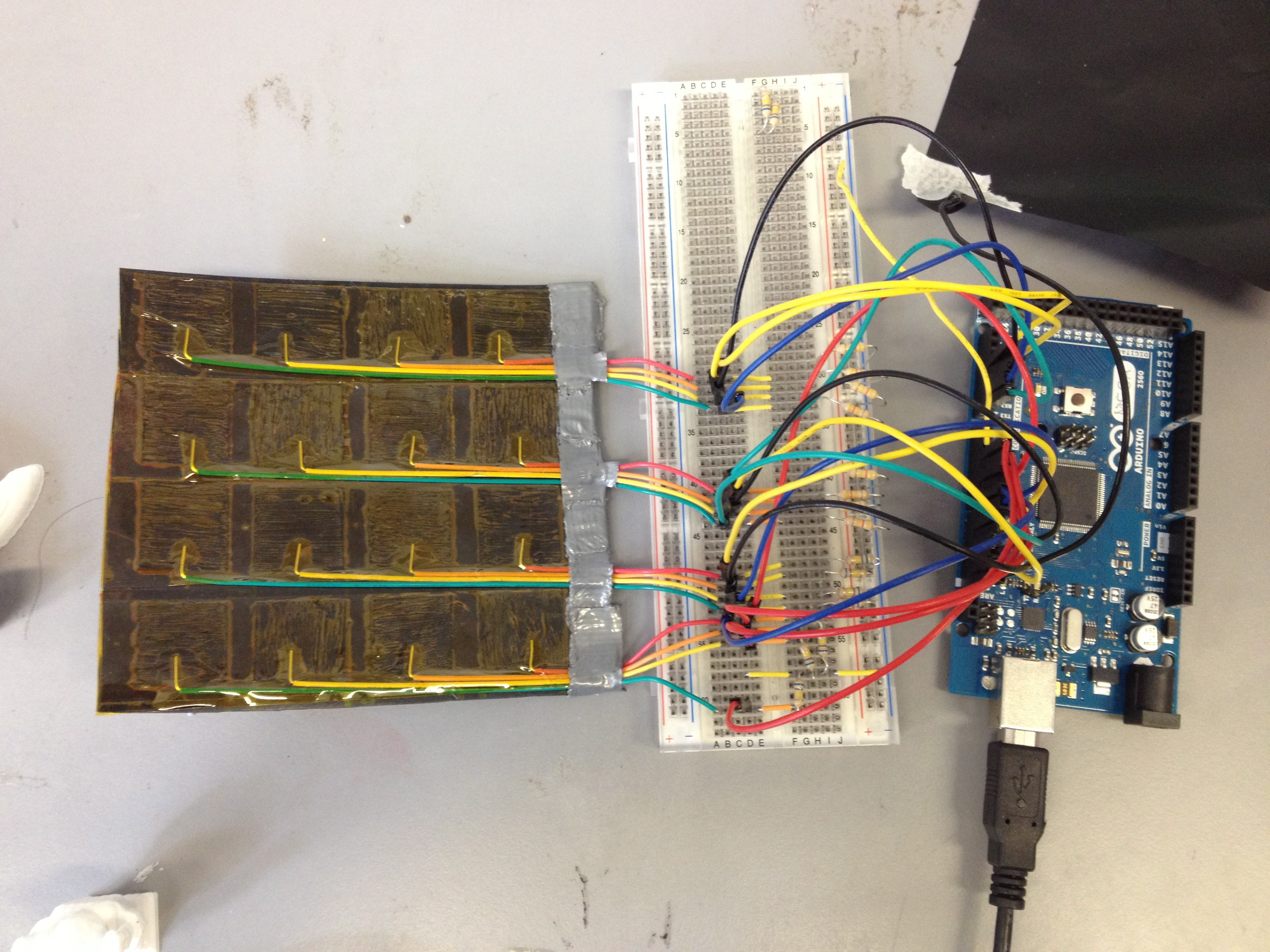

Early prototype of hand-painted sensor array wired to an Arduino microcontroller.

Capacitance-based pressure sensors were chosen over resistance-based sensors as they were shown to be far more stable, as well as being easy to implement as they only require one layer of printing. However, the current method requires an Arduino input pin for each sensor, thus arrays of more than 70 sensors would require multiplexing if this method is to be expanded further. Future circuit considerations should also include the design of bigger arrays and printed tracks for clean wiring.

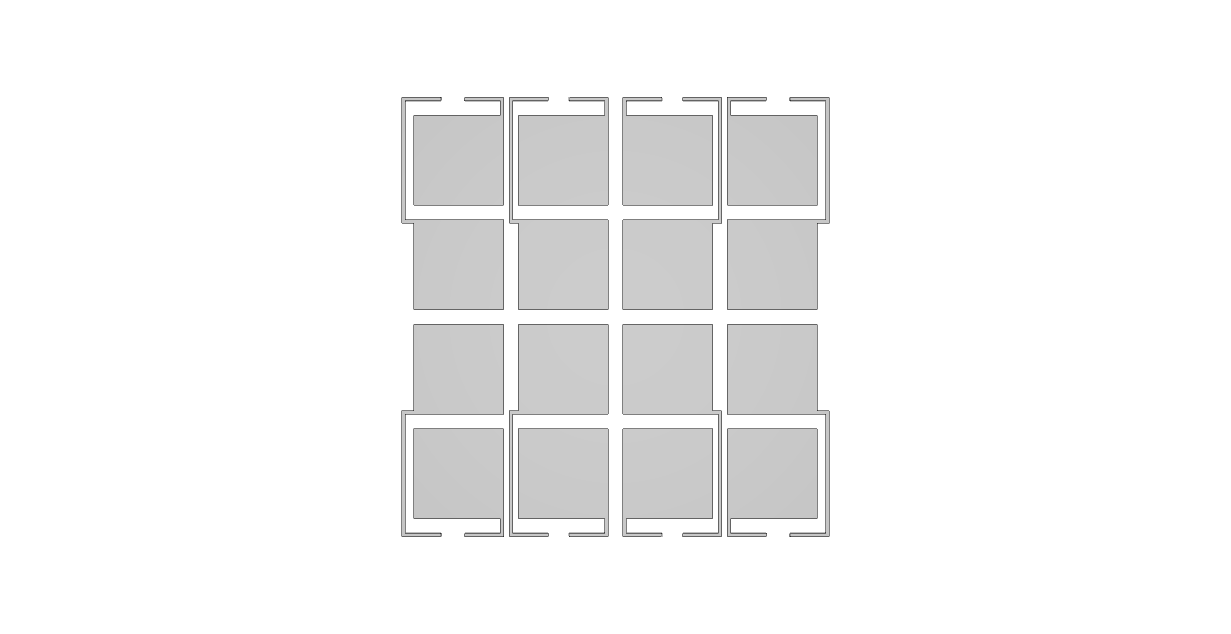

Processing sketch to visualise changes in applied pressure in prototype array.

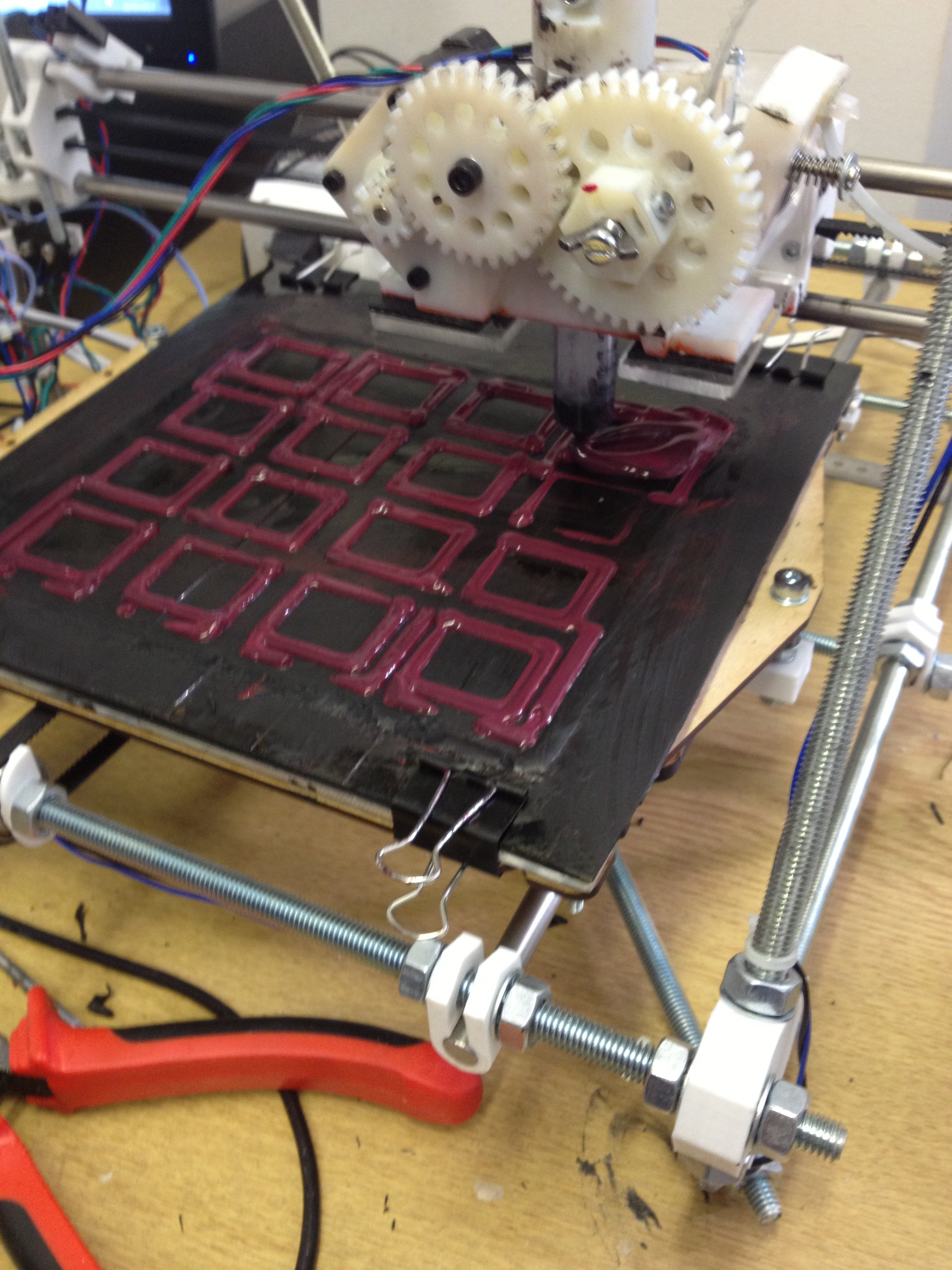

Test prints with standard acrylic paint

First tests with conductive paint, using an adapted paste extruder on the Reprap.

Graphic of STL file used for the printed prorotypes' array layout. Crocodile clips / a 'blob' of conductive paint can be used to connect the printed array leads to the Arduino pins' wires.